Design and Construction of Incubator\Egg Hatcher at Home

Introduction

In this project we design and construct an incubator .An incubator is a machine which is use for hatching a chicken eggs. This incubator can almost hatch all kinds of bird eggs.This idea is also useful for infant incubator in the medical field. In infant incubator we need to control few more parameters.

There are a lots of

application of incubator project in industries .

Problem

statement

If we don’t use

incubator technology. Then it

will affect all the food industries. Chickens

are one of the most used food

item in the world.

Normally the natural Way of Eggs hatching rate are very low while in incubator

technology the rate of hatching are very high .We can produce a lots

of healthy chicks with the help of

incubator without any problems.

Objectives :

In this project we will be design

and construct an incubator. For incubator project

few parameters are needs to be control. These parameter are like a mother chicken give to there eggs to hatch them .First of

all we need an insulated box for that we need a rectangular type metal frame and all the sides of which are cover with a

glass .Inside of this box we need to control few parameters. we need to control

temperature for which we need a temperature sensor. A humidity sensor is used

to control humidity. For Air circulation we need a small Fan. We also need a

heater to maintain the incubator temperature.

We are Using Arduino uno to control all these sensors and all the

Circuits of the incubator.

Egg turner is also very important to prevent the eggs

mortality. For egg turner a large container

tray is needed to hold the eggs .the egg turner is further connected to

the DC gear motor which control its turning after every eight

hours.

Temperature: The eggs

need to be kept at 99.5 degrees at all times; just one degree higher or lower

for a few hours can terminate the embryo.

Humidity: 40 to 50

percent humidity must be maintained for the first 18 days; 65 to 75 percent

humidity is needed for the final days before hatching.

Ventilation: Egg

shells are porous, allowing oxygen to enter and carbon dioxide to exit;

incubators need to have holes or vents that allow fresh air to circulate so the

fetuses can breathe.

Scope

of my project

We can use Incubator project in both domestic and industrial

levels.

The system worked according to

specification and proved quite satisfactory. It is relatively affordable,

durable and efficient. Hence, give room for ease of operation and high level of

reliability.

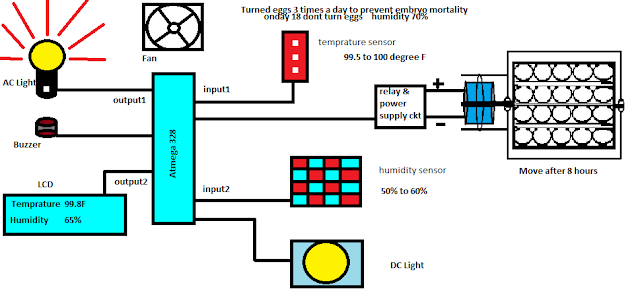

General

block diagram

Components

used in this project.

•

Electrical and Electronic

Equipment’s

• Temperature

and humidity sensor KY-015

• Temperature Sensor LM35

•

LCD

•

Buzzer

•

Heater

•

AC

Light

•

DC

Light

•

Arduino

Microcontroller

•

Relays

•

DC

Gear Motor

•

Diodes

•

Vero

board

•

Soldering

wire

•

Transistors

•

ULN

2803(IC)

•

Bread

board

•

Jumper

wires

•

Bridge

rectifies

•

Polar

capacitors

•

Lm7805

voltage regulator

•

Transformer

12volts output

•

LED,s

•

Resistors

Sketch

:

#include <LiquidCrystal.h>

int sensorValue = 0;

int analogPin = 0; // Temprature

sensor pin

int readValue = 0;

byte r; //

serial control

float temperature = 0;

float temperatureF = 0;

int Motorleft = 9; // DC MOTOR pin

int Motorright =10;

unsigned long previousTime = 0;

int comp = 1;

long interval = 28800000; //28800000 = 8 hours ,

1000msec=1sec Motor delay egg turning

LiquidCrystal lcd(12, 11, 5, 4, 3, 2);

int fan = 6; //DC Fan

int DHpin = 8; // TEMPERATURE

AND HUMIDITY SENSOR pin

int bulb=7; // Bulb pin

int tempc;

int tempcd;

int tempf;

int tempfd;

byte dat[5];

byte read_data()

{

byte data;

for(int i=0; i<8; i++)

{ if(digitalRead(DHpin) == LOW)

{ while(digitalRead(DHpin) == LOW);

delayMicroseconds(30);

if(digitalRead(DHpin) == HIGH)

data |= (1<<(7-i));

while(digitalRead(DHpin) ==

HIGH);

}

}

return data;

}

void start_test()

{

digitalWrite(DHpin,LOW);

delay(30);

digitalWrite(DHpin,HIGH);

delayMicroseconds(40);

pinMode(DHpin,INPUT);

while(digitalRead(DHpin) == HIGH);

delayMicroseconds(80);

if(digitalRead(DHpin) == LOW);

delayMicroseconds(80);

for(int i=0;i<4;i++)

dat[i] = read_data();

pinMode(DHpin,OUTPUT);

digitalWrite(DHpin,HIGH);

int a,b;

}

void setup()

{

pinMode(fan, OUTPUT);

digitalWrite(fan, LOW);

pinMode(Motorleft, OUTPUT); //Motor OUTPUT

digitalWrite(Motorleft, LOW);

pinMode(Motorright, OUTPUT);

digitalWrite(Motorright, LOW);

lcd.begin(16, 2);

pinMode(bulb, OUTPUT); //BULB output

pinMode(DHpin,OUTPUT);

Serial.begin(9600);

}

void loop()

{ readValue = analogRead(analogPin);

temperature = (readValue * 0.0049);

temperature = temperature * 100;

temperatureF = (temperature * 1.8) + 32;

delay(1000);

//lcd.clear();

lcd.setCursor(0,0);

lcd.print("TP ");

lcd.print(temperature);

lcd.print("C ");

lcd.print(temperatureF);

lcd.print('F');

start_test();

lcd.setCursor(0,2);

lcd.print("HUMIDITY ");

lcd.print(dat[0],DEC);

lcd.print('.');

lcd.print(dat[1],DEC);

lcd.print('%');

// tempc =(dat[2]);

// tempf = (tempc * 9)/ 5 +

32; // convert c to f

// tempcd =(dat[3]);

// tempfd = (tempcd * 9)/ 5 +

32; // convert c to f

if ( temperatureF >= 102) //

check temp to on or off bulb

{ digitalWrite(bulb, LOW);

digitalWrite(fan, LOW);

}

else

{ digitalWrite(bulb,HIGH);

digitalWrite(fan, HIGH);

}

if ( temperatureF <= 98) // check

temp to on or off bulb

{ digitalWrite(bulb, HIGH);

digitalWrite(fan, HIGH);

}

else

{ digitalWrite(bulb,LOW);

digitalWrite(fan, LOW);

}

delay(100);

unsigned long currentTime = millis(); // store the time since

the Arduino started running in a variable

if(currentTime - previousTime >

interval) // if it is

greater than your interval, run the if statement // compare the current time to

the previous time an LED turned on

{

previousTime = currentTime;

switch (comp)

{

case 1:

digitalWrite(Motorleft, HIGH);

delay(2400);

digitalWrite(Motorleft, LOW);

comp = 2;

break;

case 2:

digitalWrite(Motorright,

HIGH);

delay(2400);

digitalWrite(Motorright, LOW);

comp = 1;

break;

}

}

}

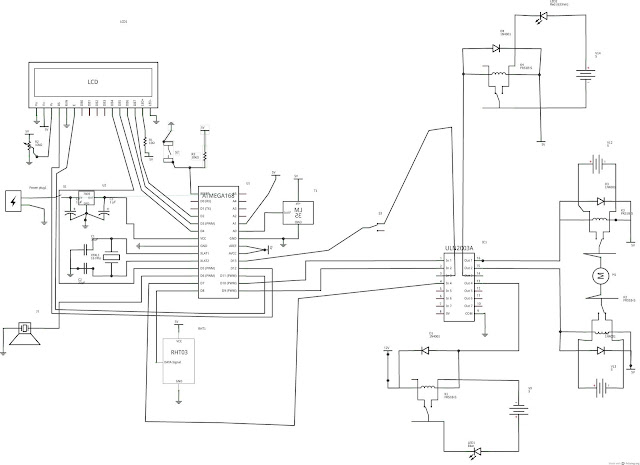

Circuit Daigram:

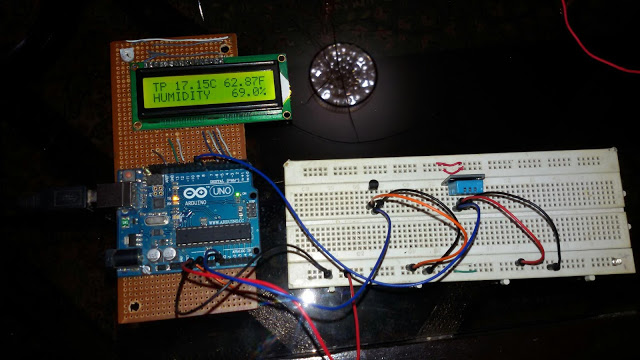

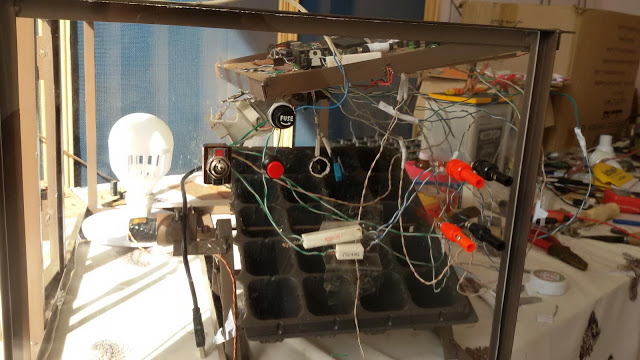

Projects images:

For Video visit my youtube channel

Follow me on

Twitter : https://twitter.com/MohsinH73145168

Thanks for sharing your research with us.

ReplyDeleteplaese are you have schema elctrique

ReplyDeleteenvoie with e-mail

Sorry did,t get u clearly?

DeleteCan u make directly through arduino uno or mega code controller for me.

ReplyDelete